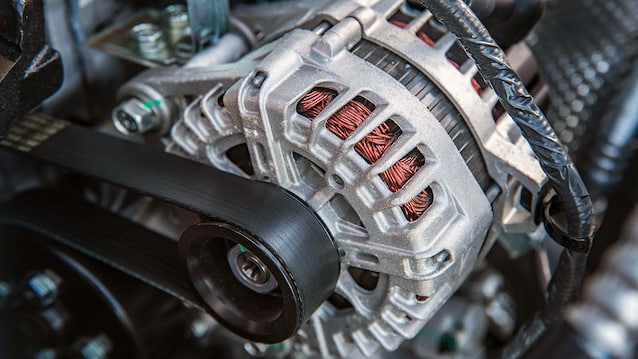

How Important is the Car Alternator: Common Failure Causes, Signs of a Bad Alternator and How to Replace One

The alternator and starter motor play an important role in the operation of your car. They are both part of the engine’s charging system, and their job is to turn the car’s generator (or dynamo), which in turn produces electricity that then powers the battery and starter motor.

When the car is running, the alternator charges the car’s battery as it generates extra power needed for the various electrical components that rely on a steady supply of current while they work. The starter motor uses this charge to generate enough power to turn over the engine when it is started or to provide extra power when the car is running at high RPM.

When the engine is turned off, the alternator continues to charge the battery as long as there is some amount of resistance in the vehicle’s electrical system (e.g., a light bulb that remains on). If there were no alternator or its output was disconnected, the battery would discharge very quickly and not have enough juice left over to turn over the engine or supply power to various electrical components when needed. In other words, the car would die.

Because of this essential function, you should have your alternator checked when it begins to show signs of wear and tear or if its output begins to diminish considerably over time. Replacing an alternator is not a difficult job for a skilled mechanic, but it can be expensive. And if you’re going to spend that kind of money, why not just get a new one?

Common Causes of Alternator Failure

The following are a few common causes of alternator failure:

- The belt that drives the generator has become stretched and no longer turns the rotor at a consistent rate. This results in poor charging performance and battery discharge.

- Dirt, grease and oil have accumulated on various components inside the alternator housing, preventing proper operation of the unit.

- The brushes in the alternator’s rectifying regulator (which converts alternating current into direct current) are worn out or broken.

Signs of a Bad Alternator

Here are the most common signs of a bad alternator:

- The battery gets discharged very quickly even when there are no electrical components in the car that require power (e.g., light bulb remains on).

- When you turn on some electrical component, there is no immediate response from the starter motor or other parts of the charging system (e.g., radio, lights).

- The engine starts to make a “clicking” sound when it is turned over or running at high RPM. This is because there is not enough current coming from the battery to power all the electrical components of the car at once.

- The dashboard lights up like a Christmas tree whenever you turn on the headlights, radio or other electrical components. This indicates that there is too much current flowing through various parts of the charging system and its circuits (e.g., fuses).

- The battery has been getting overcharged, and this can be seen by a buildup of bubbles on the top surface of its electrolyte. If left unchecked, these bubbles will eventually form cracks in the lead plates inside the battery’s cells, causing them to lose their capacity for holding charge.

Steps to Replacing an Alternator

Alternator replacement is pretty straightforward if you have basic mechanical skills and know how to use tools. You need to get a new alternator from an auto electric part store, but before doing so check out some of the following tips:

- Make sure that the new alternator will fit into your car’s engine compartment. If it is too big or small, you’re going to have a hard time installing it properly.

- Check out the wiring diagram on the back of the unit and make sure that its wires are long enough for you to reach them from their designated spots in the engine compartment all the way down to their connection points under the hood. You don’t want to cut any wires, as this will make it difficult for you to reinstall the alternator in its place.

- Make sure that the new alternator comes with a belt and pulley assembly (or “fan”). If not, then you’ll have to get one from an auto electric part stores.

- Don’t forget to check out the various mounting brackets on the unit’s backside. They are usually colour coded so that they can be installed in their proper places without further complications. You’ll need a set of tools and some basic knowledge about car engines to perform this job. If you don’t have these, then it’s best that you get someone with experience to help you out.