Packaging Prowess: A Beginner’s Guide to Using the Right Supplies

In an increasingly competitive retail and warehouse industry, businesses are more pressured than ever to stay on top of their packaging game. From protecting goods in transit to providing a sleek, professional presentation for customers, the way each product is presented can have a major impact on the overall success rate of a certain brand.

While many businesses nowadays are trying to outsmart their competition by thinking of the next big innovation, it’s often the simplest things that make the biggest difference. When you stick to the tried-and-tested basics and perfect the age-old essentials, you have a greater chance of keeping your warehouse well-organised and boosting efficiency in the manufacturing process. One of these fundamental basics is using the right packaging supplies, which can determine the safety of your product during transport, storage, and delivery.

What Are the Items Used in Packaging?

Naturally, the exact supplies that you will need for your particular business will depend on the type of products you handle, their fragility and weight, as well as the storage and shipping conditions they will need to endure. However, several items have a universal application in the overall process.

Tapes and Adhesives

There’s hardly a package that doesn’t require at least some form of adhesive. Whether it’s to seal a box, secure a label, or protect an item from shifting inside the box, tapes and adhesives are essential in keeping your goods safe and presentable. Sure, the former may seem like a no-brainer given its wide array of uses, but adhesives also play a crucial role in ensuring that labels and other packaging materials stay put during the shipping process.

One thing that gives low-viscose hot glue sticks an edge over other adhesives is that they have a longer shelf life and are cost-effective for both large and small-scale businesses. They consist of a unique water-based formula that ensures minimal shrinkage and can be dispensed quickly for maximum productivity. At the heart of their ingredients list is a blend of EVA (Ethylene Vinyl Acetate), APAO (Amorphous Poly Alpha Olefin), and PA (Polyamides) which acts as a bonding agent and provides high tensile strength.

The EVA is what makes the adhesive flexible and provides resistance to both hot and cold temperatures. The APAO works similarly, but its strength lies in providing better peel resistance and a waterproof finish. Lastly, the PA – commonly known as ‘nylon plastic’ – ensures the glue has a high impact resistance and can adhere to various surfaces, even those made of plastic or metal.

When all of these components work together in hot glue sticks, they form a formidable adhesive that can meet all of your packaging needs with ease. To dispense the formula, you’ll need a hot glue gun, and for accurate application, ensure the nozzle is clean before use. Holding at an angle of 45 degrees while in operation should give you a smooth, even seal across your package.

Generally speaking, glue sticks for glue gun application come in either a clear or yellow tint and can be used on paper, cardboard, plastic, fabric and many other packaging materials. Upon application, the gun melts the formula and squeezes it out as a thin, even line, which dries quickly and delivers a strong, long-lasting bond.

Bubble and Stretch Wrap

While adhesives may be essential for storing and shipping packages, they aren’t always enough to provide the necessary protection for delicate items. In these scenarios, bubble wrap offers an excellent solution as it provides a cushioned layer of air around delicate or fragile goods. Aside from being lightweight and quite affordable, bubble wrap is also versatile and can be cut to size depending on the items’ dimensions.

For larger or heavier objects, stretch wrap may prove more effective. It works similarly to the bubble variety in that it secures goods with a stretchy and flexible film. However, because of its stronger composition and ability to withstand higher levels of pressure, you can use stretch wrap to hold goods in place more securely and avoid any potential damage.

Boxes and Packages

The backbone of any packaging process is the actual box or package that will hold your product. While their designs may vary from one manufacturer to another, the standard options in terms of materials include cardboard, corrugated fiberboard, and plastic.

The first option is typically the most cost-effective and offers a high level of customizability where print and design are concerned. Corrugated fiberboard, on the other hand, is much sturdier and offers more significant protection against external pressure or impact. You’ll find that many shipping companies use this material to package goods precisely because it can withstand heavy handling.

Lastly, plastic packages are a common and more accessible option than the other two. They are lightweight, resistant to water and particles, and can also be environmentally friendly options if made from recycled materials. But even in their simplicity, they don’t compromise on their protective abilities.

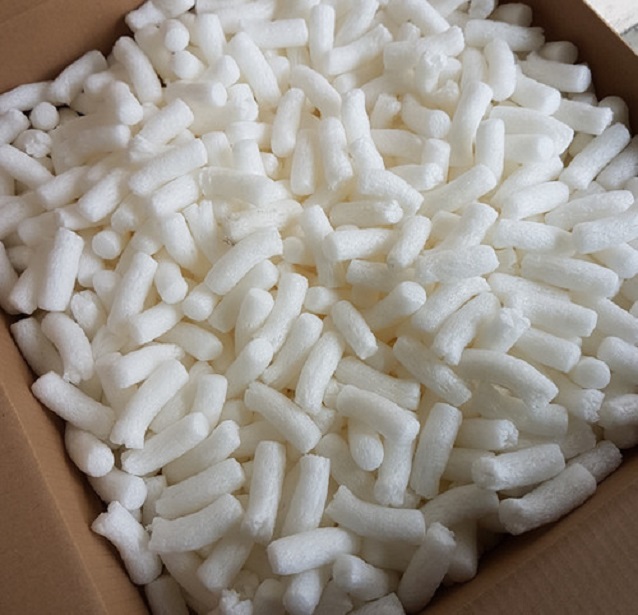

Packing Peanuts

Also known as polystyrene chips, packing peanuts are those small pieces of foam you often find at the bottom of packages. While they may seem like just small bits of debris, their function is more than just filling up the inside of a package. In fact, by filling up the extra space, they prevent any shifting of goods during shipping and deliver extra cushioning against shock or impact.