The Importance of Catalytic Converters

Car upgrades take different shapes and deliver different results. Most tuning projects where extra power is the main goal start by improving airflow in and out of the vehicle. Air intakes, exhaust piping and specialist parts like high-flow catalytic converters are some of the more common parts that aid airflow, improve engine performance and filter out toxic pollutants.

Catalytic converters have been integral to all cars since the parts were mandated for regular use in the late 1970s. This oval or cylindrical metal canister lines the exhaust piping and is tasked with converting harmful substances from the combustion process into more manageable, less toxic gases. Chemical processes are initiated by platinum, palladium and rhodium lining a honeycomb internal structure, converting carbon monoxide, nitrogen oxides and harmful hydrocarbons into carbon dioxide, nitrogen gas and water vapor.

Besides containing air pollution and promoting clean air quality, catalytic converters also have a positive impact on public health, with lower asthma and respiratory cases. The parts also reduce fuel consumption, ensure engines run more efficiently, and lower overall stress and wear levels on engines. As such, they can also be used as performance parts, particularly when controlling exhaust backpressure and optimizing air-fuel ratios for consistent power delivery.

Anatomy of Catalytic Converters

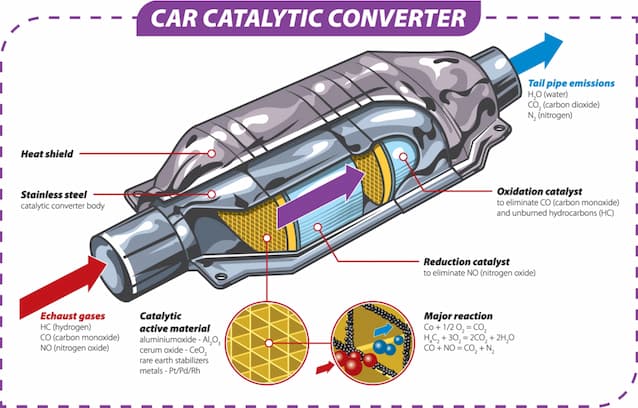

To understand how converters work, let’s consider the individual parts. This includes durable steel outer shells in a ribbed design, which prevents expansion and distortion, keeping the part aligned with the exhaust piping and preventing unwanted vibrations. The outer casing also forms channels that protect the internal catalyst cushioning mat from hot gases.

Central to the conversion process is the monolithic free-flowing substrate made of a mix of precious metals and catalysts, such as platinum, palladium, and rhodium. This initiates a chemical process when coming into contact with heated exhaust gases. The precious metals are dispersed in a rough, irregularly shaped washcoat, made of aluminum, silicone or titanium oxides. Cushioning the substrate is a metal or ceramic fiber mat. This also seals the converter and protects the housing from high temperatures.

Catalytic converters work with oxygen sensors located before and after the converter casing, in separate exhaust bungs. These provide vital vehicle data, including catalytic converter efficiency and air-fuel ratios.

How They Work

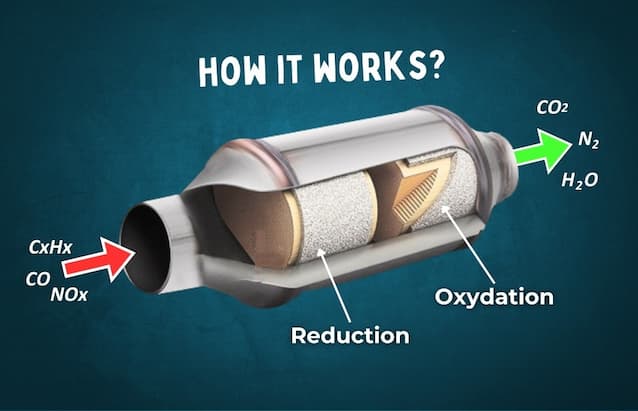

Breaking down toxic and harmful pollutants involves a series of chemical processes. Oxidation processes target carbon monoxide and unburned hydrocarbons (fuel remnants) by absorbing them through the catalyst and breaking their molecular bonds. This yields carbon dioxide and vapor. Three-way converters also involve reduction, breaking down toxic nitrogen dioxides into harmless nitrogen and oxygen. These also combine with diesel particle filters (DPFs) to reduce higher nitrogen oxide and particulate matter content in diesel fuel. With over 90 per cent of harmful combustion pollutants converted, catalytic converters contribute to cleaner air quality.

Common Types

Newer gas cars have three-way converters. These consist of separate oxidation and reduction catalysts that are more efficient in dealing with toxic gases and particulate matter, significantly reducing the environmental impact of carbon monoxide, complex hydrocarbons and nitrogen oxides. Older gas and diesel cars use oxidation converters, primarily targeting carbon monoxide and hydrocarbons. Lastly, newer diesel engines (2007 onwards) also have DPFs that deal with harmful diesel particulates and soot.

Signs of a Bad Catalytic Converter

- Reduce power and poor acceleration: Converters can get clogged, leading to airflow restrictions and increased backpressure. This can eventually choke the engine at the intake end, leading to reduced efficiency and lower power. A noticeable change is the erratic reaction to throttle input, with slower acceleration.

- Poor fuel economy: Increased backpressure is read by oxygen sensors as high oxygen content, meaning the ECU compensates by spraying more fuel to reach the desired fuel ratio of 14,7:1. The rich mixture also leaves an unpleasant fuel smell besides costing you more.

- Vibrations, rattling and unusual noises: Damaged substrates, loose housings and other issues can cause audible vibrations and rattling.

- Check engine light: Faulty converters feed incorrect information to the ECU via sensors, and this can trigger a trouble code.

While mandatory, a faulty converter negatively impacts engine performance by messing with pre-mapped air-fuel ratios. Incomplete combustion, misfires, rough idling, overheating and engine fires aren’t uncommon. Moreover, you’ll want an after market catalytic converter if yours has been stolen. Converter theft is on the rise, with the high value of platinum, palladium and rhodium.

How a High-Flow Catalytic Converter Improves Performance

High-flow catalytic converters differ from standard types in structure, with less dense catalyst materials or larger substrates, ensuring smoother gas flow. The less restrictive design reduces the buildup of backpressure within the exhaust, helping to improve combustion efficiency. This directly translates to increased power and torque, while still meeting emissions targets. More noticeable gains are in already tuned cars, with changes to the ignition timing using new cams, bigger wastegates for increased turbo boost and other performance upgrades. High-flow cats are also installed alongside performance exhausts, with revised headers and downpipes, and wide-diameter piping.