Suspension Modification: The Importance of Truck Leveling Systems

Pickup trucks top sales charts due to their versatility and utility. They’re the vehicle you want in demanding towing and hauling tasks. And with decently durable and capable suspension setups straight from the factory, the only vehicle that can handle tough terrain without any expensive mods. Other bonuses are big, powerful engines, decent comfort levels and the all the space you need for laid-back mile-crunching drives.

Another selling point is the availability and huge assortment of accessories and aftermarket parts. Anyone wanting to modify the looks of their truck or fit bigger tires for even better off-roading performance, a custom truck leveling system is a simple and affordable solution. This fits to the front axle, and helps level out the front and rear when viewing the truck from the side.

Truck Leveling Basics

Most pickup trucks have a defined amount of rake in the factory design. This means the rear is somewhat lifted, and fitted with durable leaf springs to cope with the weight of loads in the truck bed, or when towing trailers and boats. The intention is to level both axles when the truck is loaded and ensure even traction and control through all four tires.

While many truck owners just like the form factor and extra power trucks provide, not many use the bed on a regular basis. This means the front will always sit somewhat lower. To even out both ends, and allow for bigger tires or front-end additions like bull bars, a levelling kit is the aftermarket addition that ticks all the right boxes. It’s cheap, easy to install and doesn’t change the factory geometry like custom lift kits. What’s more the few added inches in ground clearance help with performance, especially where the asphalt ends.

What’s in a Leveling System?

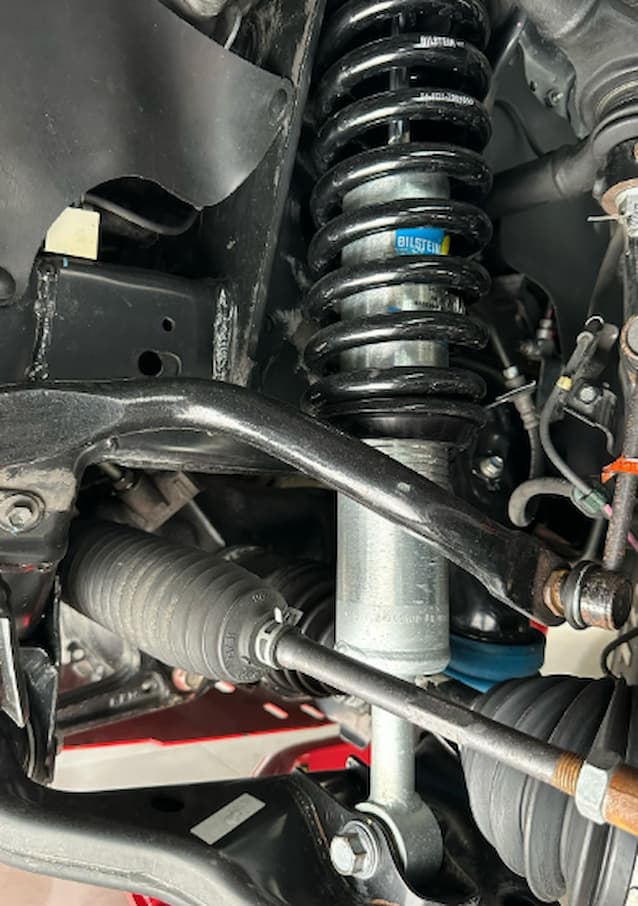

Leveling systems for trucks come in several different configurations with different parts. The most common are spacer systems which lift the front by adding a durable metal or polyurethane spacer between the strut and chassis. These are preferred if you need something that’s simple, cost-effective and easy to install.

Similar in purpose and design are puck systems. These use small cylindrical blocks installed on top of the strut assembly. On a similar note, strut extension kits include extensions (in steel, aluminum or polyurethane) mounted on top of the existing strut assembly to increase the front suspension height. All types are cheap, easy to find and installed within minutes.

For trucks with independent front suspension and included torsion bars (think the F-150 and Silverado among other models) torsion bar key kits involve more work as they require removing stock parts. The replacement torsion bar keys are sturdier and better built than factory variants and provide more customization with adjustable lift heights. Lift of 1 to 3 inches is achieved by adjusting the position of the torsion bar (itself a spring) within the frame crossmember.

To achieve more lift, you’ll be looking at aftermarket front strut assemblies. These consist of completely new struts, springs and mounting hardware. The added cost, timely installation and complexity though aren’t worth the improved handling or increased height for most truck owners.

Why Have a Leveling Kit Fitted to Your Truck?

There are undeniable benefits that a purpose-built truck leveling system offers:

- Improve stance – resolve rake and get a more aggressive, lifted look befitting of a vehicle this size.

- Ability to fit larger tires – raising the front means more space for large-diameter wheels and tires without rubbing against fenders or bumpers. This is the affordable way to get the clearance for off-roading tires with more aggressive treads.

- Enhanced off-roading performance – larger tires and improved approach (and departure angles) are prerequisites for improved maneuverability and control on loose ground and tough terrain.

- Lifted ride height – the few inches of added ground clearance go a long way in the technical stuff. Trucks can negotiate larger obstacles without sustaining damage to the undercarriage, transmission or exhaust.

- Factory handling – simple parts and minimal but effective lift don’t alter the truck geometry, meaning the steering remains composed and equally responsive.

Buying Considerations

Before committing to truck leveling systems, a few key buying factors will help you get what’s right. The main concern is choosing the right type in terms of fit and truck compatibility. Aside from costly full strut replacements, some types like torsion key systems are compatible only with certain truck makes and models. Spacer systems still remain a viable option for most vehicles though, largely due to their simplicity and low cost.

Another consideration is build and materials. These need to be durable and up to the task while working in harsh conditions.

Lastly, decide whether a lift kit makes more sense, especially if you need more clearance or bigger tires and do more off-roading than most truck owners. Just bear in mind the complexity and cost of multiple suspension parts like new shocks and longer springs and control arms. For more people though a simple leveling kit with just the right amount of front-axle lift meets most needs.